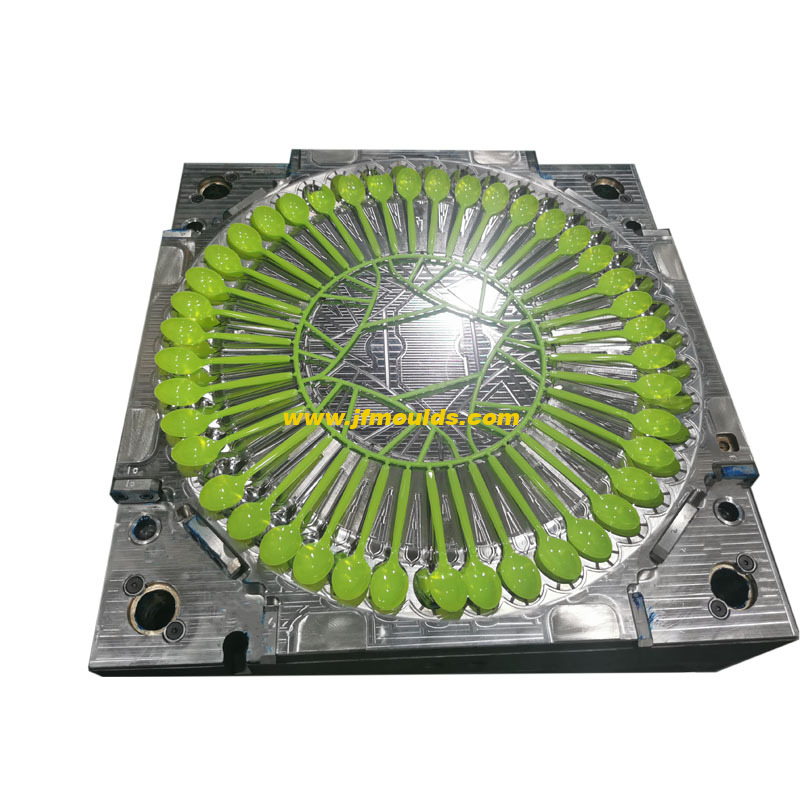

Cetakan injeksi sendok plastik

Rincian

Produsen sendok plastik

Sebagai salah satu produsen cetakan sendok plastik domestik paling kompetitif dan terkemuka, Jiefeng Cetakan telah berfokus pada penelitian, pengembangan, dan produksi cetakan tersebut selama lebih dari sepuluh tahun. Dengan teknologi canggih, pengalaman yang luas, dan sistem kontrol kualitas yang ketat, kami selalu dapat memberikan pelanggan global presisi tinggi, sangat tahan lama, dan cetakan sendok plastik berkualitas tinggi, membantu produsen kebutuhan harian menciptakan produk dengan daya saing pasar yang lebih kuat.

Informasi Dasar :

| Nama cetakan | Cetakan injeksi sendok plastik |

| Bahan cetakan | P20,45# Baja, S136, H13.718H, dll. |

| Pelari | Pelari panas |

| Merek pelari panas | YUDO |

| Perangkat lunak desain | Dan |

| Cetakan kehidupan | 1.000.000 |

| Waktu pengiriman | 35-60 hari |

| Bahan plastik | PP PC ABS PE PVC ABS+PC PS.ETC. |

| Periode garansi | setahun |

| Rongga cetakan | Rongga tunggal |

| Jenis gerbang | Gerbang pinpoint, gerbang tepi, gerbang sub, gerbang film, gerbang katup, gerbang terbuka, makan |

| Perlakuan permukaan jamur | Edm, tekstur, pemolesan gloss tinggi |

| Sistem Kualitas | SGS |

| Asal | Dibuat di Cina |

| Instalasi | tetap |

| Rongga | Tunggal/multi |

| Spesifikasi | Tergantung pada persyaratan pelanggan |

| Sistem pendingin cetakan | pendingin air atau pendingin perunggu berilium. dll. |

| Perawatan panas jamur | quencher, nitridasi, tempering.etc. |

| Ukuran Pengemasan (mm) | 500*500*450 |

| Berat kemasan | 650kg |

Keuntungan kami:

1. Keunggulan teknologi dan proses:

Possessing professional mold design capabilities (such as optimizing structures using CAD/CAM/CAE software), being familiawith the forming characteristics of different materials (such as PP, ABS, PC), capable of solving mold manufacturing problemswith complex structures (such as thin walls, multi-cavities, and precise patterns), ensuring product accuracy and consistency

2. Kemampuan Optimalisasi Biaya:

Melalui produksi skala besar, integrasi rantai pasokan (seperti pengadaan massal bahan baku). dan Desi yang dioptimalkan memadukan umur, biaya setiap cetakan dan kerugian dalam produksi cetakan injeksi berikutnya dapat dikurangi. Pada saat yang sama, layanan "cetakan + iniection cetakan" yang diintegrasikan dapat disediakan untuk mengurangi biaya tambahan forcustomer koneksi mult-link.

3. Efisiensi Pengiriman dan Layanan

Dengan proses dan peralatan produksi yang matang (seperti pusat permesinan CNC dan mesin EDM EDM). Siklus pengembangan jamur dapat diperpendek (biasanya dari desain ke cetakan percobaan dapat dikompresi hingga beberapa minggu). Pada timewe yang sama menyediakan pemeliharaan setelah penjualan (seperti perbaikan dan pemeliharaan cetakan) dan layanan modifikasi cetakan cepat untuk mengurangi waktu produksi pelanggan.

4. Kemampuan Kontrol Kualitas:

Menetapkan standar inspeksi kualitas ful-proses (dari entri bahan baku, inspeksi proses pemrosesan hingga sampleverifikasi), dan beberapa produsen yang memperoleh 1S0 dan sertifikasi sistem lainnya dapat memastikan operasi stabil jangka panjang dari MOLDS dan mengurangi laju scrapping produk yang disebabkan oleh cacat cetakan

Jiefeng Cetakanakan memberikan analisis FOW pelanggan. dan menggunakan perangkat lunak simulasi untuk memverifikasi detail dasar dari kabel fiing ProcessDissolution, deformasi, dan desain die lainnya. Karakteristik ini akan menentukan kualitas tinggi die untuk memastikan teaskurasi tahap awal proyek dan untuk memastikan keberhasilan di T1

Kami menyediakan berbagai teknologi pemrosesan, hingga lima perangkat lunak Axesthe cocok untuk semua pemrograman 2D, 3D, dan lima sumbu. Mesin ini dilengkapi dengan pengubah alat otomatis dan alat kalibrasi laser.

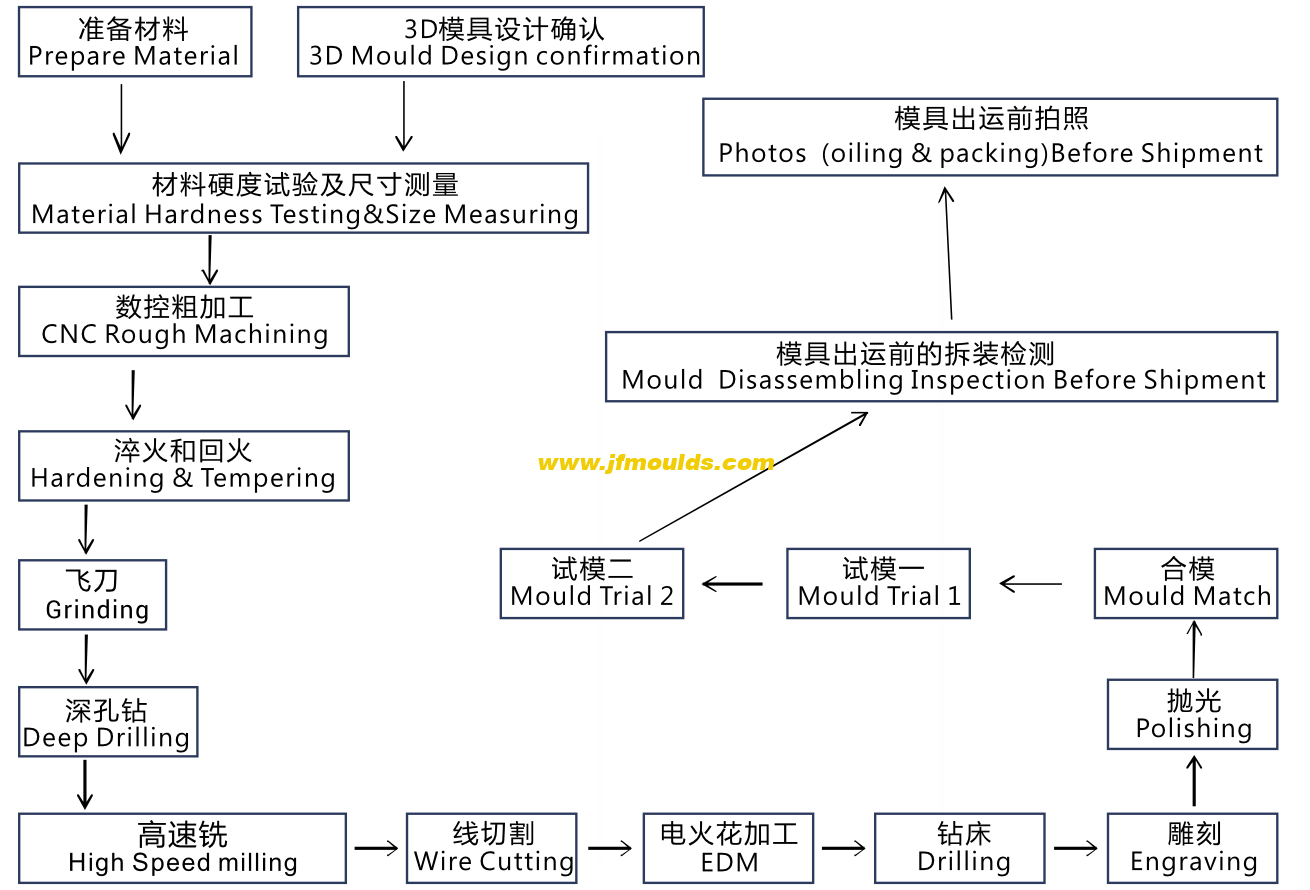

Bagan aliran cetakan:

Packaging and transportation:

Jiefang Mould, with its strict shipment inspection standards, systematic packaging protection system and rapid response after-sales mechanism, has built a full-chain safety guarantee closed loop from the factory to the customer's production line, ensuring that every set of moulds can be safely and reliably delivered and put into production.

1. Mold shipment: Multi-dimensional inspection builds a solid quality defense line

To ensure the quality of molds from the root, Jiefang has established a multi-stage and multi-level inspection mechanism. From the dimensional accuracy and structural strength of the molds to their surface finish and functional compatibility, all are subject to strict inspection by professional testing equipment and experienced quality inspection teams to ensure that each set of molds meets or even exceeds industry standards and customer requirements.

2. Professional Packaging: Standardized processes create a "safe fortress"

Jiefang adopts a standardized and refined full-process packaging technology to build an impregnable "safety fortress" for molds:

Cleaning and rust removal: Through professional cleaning equipment and rust removal processes, thoroughly remove oil stains, dust and rust on the surface of the mold to ensure its cleanliness.

Anti-rust protection: High-quality anti-rust materials are selected, and multiple anti-rust treatments such as spraying and soaking are adopted to coat the molds with a "protective armor", effectively resisting the risk of rusting during transportation and storage.

Sealed packaging: Use packaging materials with excellent sealing performance to tightly wrap the molds to prevent the invasion of external factors such as air and moisture.

Sturdy packaging: According to the size and weight of the mold, customize a sturdy packaging structure, such as high-strength wooden boxes, metal frames, etc., to ensure that the mold is not damaged by collision or compression during transportation.

3. Full-cycle technical support: One-stop service ensures smooth production

Warranty period: We offer industry-leading warranty period services. During the warranty period, if there are non-human-induced quality issues with the mold, free repair or replacement services can be enjoyed.

Standardized mold frame and maintenance for internal after-sales response: Establish a 7× 24-hour rapid response mechanism. After receiving the customer's after-sales request, the technical team will provide remote guidance or on-site service in the first instance. At the same time, standardized mold bases are provided to facilitate mold maintenance and upgrades, reducing maintenance costs.

Professional assembly guarantees post-warranty technical support: Equipped with a professional assembly team, we can provide on-site assembly and debugging services for molds to customers, ensuring rapid production of molds. Even after the warranty period, we still provide continuous support such as technical consultation and paid maintenance to help customers achieve long-term stable production.

From the rigorous layer upon layer of shipment inspection to the comprehensive packaging protection, and then to the always-on after-sales support, Jiefang Mould, with its professional, meticulous and full-cycle service system, ensures that customers have no worries at every stage of mold delivery and use, thereby fully guaranteeing their production efficiency and economic benefits, and becoming a solid backing for customers' mold procurement and production.