Analisis mendalam industri cetakan injeksi

Analisis mendalam industri cetakan injeksi

I. Gambaran Umum Industri Cetakan Injeksi

(1) Definisi dan fungsi cetakan injeksi

Cetakan injeksi adalah alat yang digunakan untuk cetakan plastik. Mereka menyuntikkan plastik cair ke dalam rongga cetakan dengan bentuk tertentu, dan setelah pendinginan dan pemadatan, mereka membentuk produk plastik dari bentuk yang diinginkan. Cetakan injeksi memainkan peran penting dalam proses produksi produk plastik. Mereka menentukan bentuk, ukuran, presisi, dan kualitas permukaan produk plastik dan banyak digunakan di banyak industri seperti mobil, peralatan rumah tangga, elektronik, pengemasan dan perawatan medis. Mereka adalah tautan kunci yang sangat diperlukan dalam manufaktur modern.

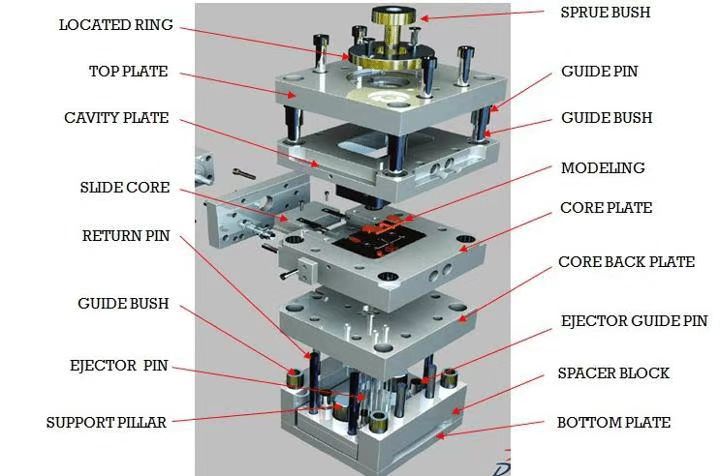

(2) Klasifikasi dan struktur cetakan injeksi

Cetakan injeksi dapat diklasifikasikan ke dalam berbagai jenis berdasarkan kriteria yang berbeda. Yang umum termasuk cetakan injeksi wajah berpisah tunggal, cetakan injeksi wajah ganda, cetakan injeksi pelari panas, dan cetakan injeksi yang dibantu gas, dll. Struktur dasarnya biasanya terdiri dari komponen pembentukan, sistem gating, komponen penuntun, mekanisme demolding, sistem regulasi suhu dan sistem pembuangan, masing-masing bagian memiliki fungsi spesifik dan bekerja dalam koordinasi untuk kemajuan kemajuan.

Ii. Situasi pasar saat ini dari industri cetakan injeksi

(1) Ukuran pasar global dan tren pertumbuhan

Dalam beberapa tahun terakhir, pasar cetakan injeksi global telah menunjukkan tren pertumbuhan yang stabil. Menurut data dari lembaga penelitian pasar, ukuran pasar cetakan injeksi global terus berkembang dalam beberapa tahun terakhir dan diharapkan untuk mempertahankan tingkat pertumbuhan tertentu di tahun -tahun mendatang. Ini terutama disebabkan oleh pemulihan dan pengembangan industri manufaktur global, terutama meningkatnya permintaan produk plastik di industri seperti mobil dan elektronik.

(2) Posisi dan karakteristik pengembangan pasar Cina

Sebagai basis manufaktur global yang signifikan, Cina juga memegang posisi penting dalam industri cetakan injeksi. Ukuran pasar cetakan injeksi di Cina sangat besar dan tumbuh pada tingkat yang relatif cepat. Di satu sisi, pengembangan yang kuat dari manufaktur dalam negeri telah menyediakan ruang pasar yang luas untuk industri cetakan injeksi; Di sisi lain, perusahaan cetakan injeksi Cina telah terus meningkat dalam hal tingkat teknologi, kualitas produk dan efisiensi produksi, secara bertahap membuat tanda mereka di pasar internasional. Sementara itu, pasar cetakan injeksi Tiongkok juga menunjukkan karakteristik pengembangan regional yang tidak seimbang, terutama terkonsentrasi di daerah yang dikembangkan seperti Guangdong, Jiangsu dan Zhejiang.

(3) Analisis Permintaan Pasar

Permintaan Industri :

Permintaan cetakan injeksi di industri otomotif terutama tercermin dalam produksi produk plastik seperti interior otomotif, eksterior, dan bagian mesin. Dengan tren pengembangan ringan dan kecerdasan otomotif, persyaratan yang lebih tinggi telah diajukan untuk presisi dan kompleksitas cetakan injeksi. Industri alat rumah membutuhkan sejumlah besar cetakan injeksi untuk menghasilkan berbagai cangkang alat dan komponen internal. Beragam tuntutan konsumen untuk penampilan dan fungsi peralatan rumah tangga telah mendorong pengembangan inovatif cetakan injeksi. Permintaan cetakan injeksi di industri elektronik terutama difokuskan pada pembuatan cangkang dan komponen untuk produk elektronik seperti ponsel, komputer, dan tablet. Dengan kecepatan pembaruan dan penggantian produk yang dipercepat, persyaratan siklus produksi dan kualitas untuk cetakan injeksi juga semakin tinggi dan lebih tinggi.

Cetakan bemper pabrikan di Tiongkok (jfmoulds.com)

2. Persyaratan Produk:

Cetakan injeksi presisi tinggi dapat menghasilkan produk plastik dengan akurasi dimensi yang lebih tinggi dan kualitas permukaan yang lebih baik, memenuhi permintaan produksi produk kelas atas. Mereka banyak digunakan di bidang seperti ruang angkasa dan perangkat medis. Cetakan injeksi besar terutama digunakan untuk pembuatan produk plastik besar, seperti bumper mobil dan wadah industri. Dengan meningkatnya permintaan pasar untuk produk plastik besar, prospek pasar untuk cetakan injeksi besar juga cukup luas. Cetakan injeksi terstruktur kompleks dapat menghasilkan produk plastik dengan bentuk kompleks dan struktur internal, seperti desain selubung ponsel yang tidak teratur dan rongga bagian dalam kompleks manifold intake engine otomotif. Kesulitan teknis mereka relatif tinggi, dan permintaan pasar juga secara bertahap meningkat.

(4) Analisis Pasokan Pasar

1. Jumlah dan skala distribusi perusahaan:

Saat ini, ada sejumlah besar perusahaan cetakan injeksi di seluruh dunia, dengan skala yang bervariasi. Dalam hal skala perusahaan, ada perusahaan cetakan multinasional yang besar dan banyak perusahaan cetakan kecil dan menengah. Perusahaan besar biasanya memiliki peralatan teknis canggih, kemampuan R&D yang kuat dan sistem layanan yang lengkap, dan menempati posisi dominan di pasar kelas atas. Perusahaan kecil dan menengah memainkan peran penting di pasar tengah ke bawah berdasarkan fleksibilitas dan keunggulan biaya mereka. Di Cina, jumlah perusahaan cetakan injeksi juga cukup besar, di antaranya di Guangdong, Jiangsu dan tempat -tempat lain adalah yang paling terkonsentrasi. Di antara perusahaan-perusahaan ini, tidak hanya perusahaan skala besar yang terdaftar seperti Grup Mesin Plastik Haiti dan Chung Hsing Group, tetapi juga sejumlah besar perusahaan swasta kecil dan menengah.

2. Tingkat teknis dan kapasitas produksi:

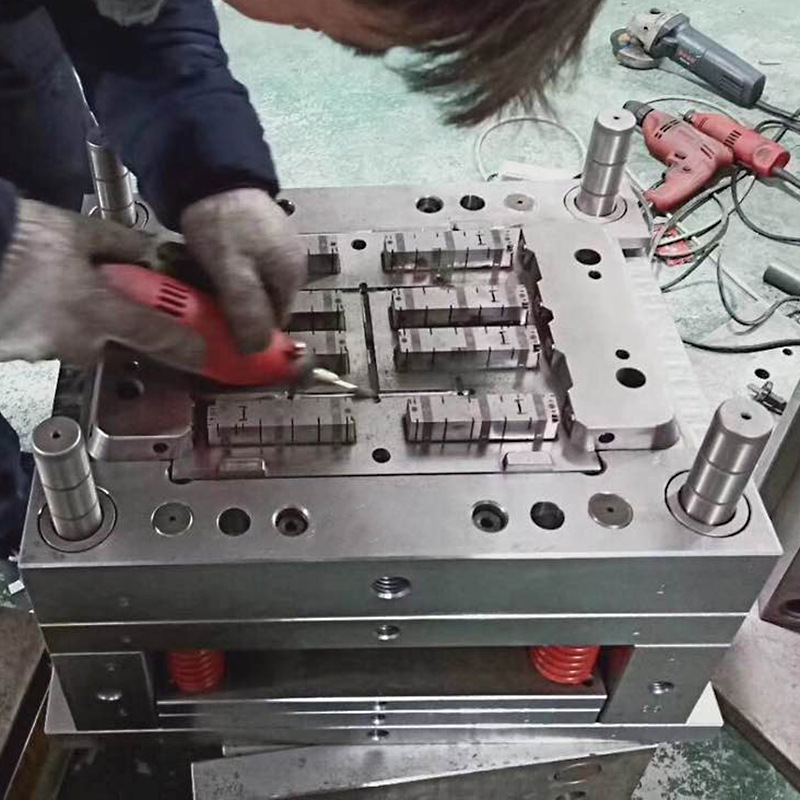

Dengan kemajuan teknologi yang berkelanjutan, tingkat teknis industri cetakan injeksi juga terus membaik. Saat ini, teknologi manufaktur cetakan injeksi canggih meliputi penggilingan berkecepatan tinggi, pemesinan pelepasan listrik, pemesinan hubungan lima sumbu, pencetakan 3D, dll. Penerapan teknologi ini telah secara signifikan meningkatkan akurasi manufaktur, efisiensi produksi dan kualitas cetakan injeksi. Sementara itu, beberapa perusahaan juga telah memperkenalkan sistem manajemen produksi cerdas, mencapai otomatisasi dan informatisasi proses produksi, dan lebih meningkatkan kapasitas produksi dan tingkat manajemen. Namun, masih ada perbedaan besar dalam tingkat teknologi dan kemampuan produksi di antara berbagai perusahaan. Beberapa perusahaan kecil dan menengah masih mengalami kesulitan tertentu dalam inovasi teknologi dan pembaruan peralatan.

Aku aku aku. Pengembangan Teknologi dalam Industri Cetakan Injeksi

(1) Teknologi manufaktur cetakan injeksi tradisional

1. Teknologi Pemrosesan Mekanik

Putar terutama digunakan untuk memproses bagian yang berputar dari cetakan injeksi, seperti inti dan pin ejector. Melalui rotasi mesin bubut dan gerakan pakan alat, benda kerja diproses menjadi bentuk dan ukuran yang diperlukan. Penggilingan dapat digunakan untuk memproses pesawat, permukaan melengkung dan rongga cetakan, dll. Peralatan penggilingan yang biasa digunakan termasuk mesin penggilingan CNC dan pusat pemesinan, yang dapat mencapai pemrosesan penggilingan presisi tinggi. Pemrosesan penggilingan digunakan untuk meningkatkan permukaan akhir dan akurasi dimensi bagian cetakan dan biasanya dilakukan setelah pemrosesan mekanis, seperti penggilingan permukaan, penggilingan silindris, penggilingan internal, dll.

2. Teknologi Pemesinan Debit Listrik

Electrical discharge forming (EDM) is a process that uses the high temperature generated by discharge to corrode metals, thereby machining the required shape and size on mold workpieces. It is particularly suitable for processing complex-shaped cavities and parts that are difficult to machine mechanically. Electrical discharge wire cutting (EDM) processing uses a moving fine metal wire as an electrode to perform pulsed discharge corrosion cutting on the workpiece. It is often used to process irregular holes and narrow slots in molds.

(2) Advanced injection mold manufacturing technology

1. Application of 3D Printing Technology in Injection Mold Manufacturing

3D printing technology, also known as additive manufacturing technology, has unique advantages in injection mold manufacturing. It can quickly produce prototypes of molds for verification and optimization of product design, significantly shortening the mold development cycle. It is capable of manufacturing complex-structured molds that are difficult to achieve through traditional processing methods, such as conformal cooling water channel molds, thereby enhancing the cooling efficiency of the molds and the quality of injection molding. It can also achieve personalized customized production to meet the special needs of different customers. At present, the application scope of 3D printing technology in injection mold manufacturing is constantly expanding, and certain progress has been made from the production of small mold components to the printing of entire molds.

2. Development and Application of Hot Runner Technology

Hot runner technology is a process in injection molding that uses a heating device to keep the plastic in the runner in a molten state all the time, avoiding the formation of solidified material in the cold runner system, thereby improving the injection molding efficiency and product quality. With the continuous development of hot runner technology, its application is becoming increasingly widespread. The types of hot runner systems are also increasingly diverse, including open hot runners and needle valve hot runners, which can meet the injection molding requirements of different plastic products. Meanwhile, hot runner technology has also made remarkable progress in temperature control, runner design and system stability.

3. The Penetration of intelligent Manufacturing Technology in the Injection Mold Industry

Intelligent manufacturing technology is an important direction for the future development of the injection mold industry. By introducing technologies such as sensors, the Internet of Things, big data, and artificial intelligence, intelligent monitoring and management of the injection mold production process can be achieved. For instance, sensors are used to monitor parameters such as the temperature, pressure and vibration of the mold in real time. Through data analysis, potential faults of the mold can be detected promptly and early warnings can be issued. Optimize the injection molding process parameters by leveraging artificial intelligence algorithms to enhance the molding quality and production efficiency of products. Automated equipment and robots are adopted to carry out operations such as loading, unloading, handling and processing of molds, reducing manual intervention and enhancing the accuracy and stability of production.

(3) Innovation and Development of Injection Mold Materials

1. Research and Application of New die Steel

To meet the requirements of injection molds for high strength, high hardness, high wear resistance and good processing performance, new types of mold steel are constantly emerging. For instance, some high-performance die steels, based on traditional die steels, have enhanced the comprehensive performance of die steels by optimizing alloy composition and heat treatment processes. Meanwhile, in response to different application scenarios of injection molds, mold steels with special properties have been developed, such as corrosion-resistant mold steels and hot work mold steels, further expanding the application scope of mold steels.

2. Application Expansion of High-Performance Plastic Materials in Injection Molds:

In addition to die steel, the application of high-performance plastic materials in injection molds is also receiving increasing attention. Some plastic materials with high strength, high heat resistance and high corrosion resistance, such as polyetheretherketone (PEEK) and polyphenylene sulfide (PPS), can be used to manufacture components of injection molds, reducing the weight of the molds and improving their insulation performance and chemical stability. In addition, the molding process of plastic materials is constantly being improved to better meet the requirements of injection mold manufacturing.

Iv. Application Fields of Injection Mold Industry

(1) The automotive industry

1.The demand characteristics of injection molds for automotive parts:

The automotive industry is one of the important application fields of injection molds, and the demand for injection molds is characterized by high precision, high complexity and mass production. There are numerous types of automotive parts, including interior parts (such as instrument panels, seats, door trim panels, etc.), exterior parts (such as bumpers, lamp covers, rearview mirror housings, etc.) and engine parts (such as intake manifolds, oil pans, etc.). These parts vary in shape and size, and thus have extremely high requirements for the design and manufacture of injection molds. Meanwhile, to meet the requirements of high efficiency and low cost in automotive production, injection molds need to have good durability and production stability, and be capable of achieving large-scale production.

2.Typical Case Analysis

Take a certain automobile manufacturing enterprise as an example. When it produced the bumpers of new models of cars, it adopted a set of high-precision injection molds. This mold adopts hot runner technology and gas-assisted injection molding process, which not only improves the forming quality of bumpers, reduces product defects, but also shortens the injection molding cycle and enhances production efficiency. In addition, the design of the mold fully takes into account the structural features and appearance requirements of the bumper. By optimizing the parting surface and cooling system of the mold, the dimensional accuracy and surface finish of the bumper are ensured, meeting the strict quality requirements of automotive enterprises for products.

(2)Home appliance Industry

1.The degree of reliance of household appliances on injection molds:

The home appliance industry is highly dependent on injection molds. Almost all the shells and internal components of home appliances need to be produced through injection molds. With the continuous development of the home appliance industry and the increasing demands of consumers for the appearance and functionality of home appliances, injection molds are playing an increasingly important role in ensuring the quality of home appliances, reducing production costs and achieving product innovation.

2. Innovative Applications of Injection Molds in the Home Appliance Industry

To meet the diverse and personalized demands of household appliances, injection molds are constantly being innovatively applied in the household appliance industry. For instance, the use of two-color injection molds enables the one-time injection molding of plastic products of two different colors or materials, offering more possibilities for the appearance design of household appliances. The thin-walled injection molding technology can be used to produce thinner and lighter home appliance shells, which not only saves material costs but also enhances the aesthetic appeal and heat dissipation performance of the products. In addition, some home appliance enterprises have also collaborated with mold manufacturers to develop injection molds with special functions, such as antibacterial injection molds and self-cleaning injection molds, endowing home appliances with new features and selling points.

Dua warna mould_taichu jiifeng Mould Co.,Ltd. (jfmoulds.com)

(3)Electronics industry

1. Application scenarios of injection molds in electronic equipment manufacturing:

In the field of electronic equipment manufacturing, injection molds are widely used in the production of casings, components and internal structural parts of various electronic products such as mobile phones, computers, tablets and headphones. With the rapid development of electronic technology, electronic products are moving towards miniaturization, thinness and multi-functionality, which puts forward higher requirements for the precision, dimensional stability and production efficiency of injection molds.

2. Mold solutions for the rapid upgrading of electronic products:

In order to meet the market demand for rapid updates and replacements of electronic products, injection mold enterprises need to constantly enhance their R&D capabilities and rapid response capabilities. On the one hand, by adopting advanced mold design software and manufacturing technologies, the development cycle of molds can be shortened; On the other hand, establishing a flexible production management system enables rapid adjustment of production plans to meet the small-batch and multi-variety order demands of different customers. In addition, some mold enterprises have established long-term strategic cooperative relationships with electronic equipment manufacturers, getting involved in the research and development and design stage of products in advance, and providing mold technical support for the innovation of electronic products.

Informasi terkait

Kartu Bisnis Baru dari Mold Capital sepenuhnya dimulai.

2025-06-19

Baru-baru ini, di situs konstruksi cetakan Huangyan manufaktur cerdas...

Evolusi koordinat tentang iterasi teknologi dan ekosistem industri

2025-07-15

Evolusi koordinat tentang iterasi teknologi dan ecosystemI industri...

Huangyan: membangun

2025-06-22

Distrik Huangyan Kota Taizhou dikenal sebagai pulkam cetakan di Tiongkok.

Cetakan injeksi: Juara tersembunyi dalam manufaktur industri

2025-07-14

Cetakan injeksi: Juara tersembunyi dalam manufaktur industri di luas...

Wawasan panorama tentang industri cetakan injeksi: penempaan ke depan dalam gelombang perubahan

2025-07-04

Wawasan panorama tentang industri cetakan injeksi: penempaan ke depan dalam gelombang...

Jelajahi industri cetakan Huangyan dalam bersama mata Deepseek

2025-06-19

1. Proses Pengembangan dan skala industri 01 riwayat Huangyan mol...