Penyebab dan solusi pengelasan yang buruk dalam cetakan injeksi, retakan produk dan deformasi produk

Penyebab dan solusi pengelasan yang burukcetakan injeksi, retakan produk dan deformasi produk

Mould_Taizhou jiifeng Mould Co.,Ltd. (jfmoulds.com)

| Cacat produk | Alasan yang mungkin | Larutan | |

| Pengelasan yang buruk | 1. Bentuk sistem gerbang tidak tepat, gerbang kecil, pelari kecil dan jalur aliran panjang, resistansi terhadap aliran material besar, dan suhu material turun dengan cepat. 2. Suhu material atau suhu cetakan terlalu rendah. 3. Plastik memiliki fluiditas yang buruk. Saat bahan dingin dicampur, kecepatan pendinginan cepat. 4. Ada kelembaban atau pelumas dalam cetakan, inflasi berlebihan bahan cair, dan agen pelepasan yang berlebihan. 5. Tekanan injeksi terlalu rendah atau kecepatan injeksi lambat. 6. Bentuk produknya buruk dan ketebalan dinding tidak rata, menyebabkan bahan cair menyatu di daerah berdinding tipis. 7. Sistem pendinginan cetakan atau knalpot yang buruk. 8. Plastik dicampur dengan bahan yang tidak dapat dicampur, minyak atau tidak memiliki demolding yang tepat. | 1. Meningkatkan sistem gerbang, meningkatkan gerbang atau pelari, mengurangi ketahanan aliran dan ketahanan aliran material, dan mempertahankan kisaran suhu material. 2. Tingkatkan suhu silinder meleleh lem dan mati. 3. Untuk bahan dengan fluiditas yang buruk, mencegah bahan dingin ditambahkan untuk mempercepat pendinginan dan mempengaruhi laju aliran. 4. Periksa lubang knalpot, keringkan dinding bagian dalam die, atau gunakan plastik, aditif, dll. Sesuai dengan proses dan standar teknis. 5. Tingkatkan nilai pengaturan tekanan dan kecepatan injeksi. 6. Tingkatkan bentuk produk atau tingkatkan waktu siklus cetakan injeksi. 7. Periksa sistem pendingin dan kondisi lubang knalpot. 8. Periksa apakah plastik bebas dari kontaminasi, bersihkan dinding cetakan, dan oleskan agen pelepas cetakan yang sesuai untuk memecahkan produk. | |

| Retak produk | 1. Plastik terkontaminasi, kurang kering atau mengandung zat yang mudah menguap. 2. Sebagian besar bahan plastik dan daur ulang dicampur bersama -sama menyebabkan arah yang berlebihan dari penyusutan plastik atau distribusi pengisi yang tidak merata. 3. Desain demolding yang tidak tepat, dinding produk tipis, lereng demolding kecil, sudut tajam dan takik, yang dapat dengan mudah menyebabkan konsentrasi stres. 4. Improper positioning of the ejector pin or ring, or improper forming conditions, excessive stress, and poor ejection. 5. The temperature of the tool and die is too low or uneven. 6. The injection pressure is too low and the injection speed is too slow. 7. The injection time and holding pressure time Settings are too short. 8. The cooling time is not properly adjusted, either too long or too short. The cooling of the products after demolding or post-treatment is uneven, or the mold release agent is used improperly. | 1.Check whether the plastic is contaminated or adulterated, etc. 2. Strictly control the proportion of plastic recycled materials and waste materials added to ensure that the plastic can be well plasticized. 3. Modify the die design to eliminate small slopes, sharp corners and notches. 4. Adjust and install the ejector pin device to ensure that the ejector pin can smoothly push out the product without any collision. 5. Adjust the temperature of the die and tool to maintain it at normal or increase it. 6. Increase the set values of the injection pressure and speed parameters. 7. Add the setting of parameters for injection time and holding pressure time. 8. According to the specific conditions of the products, adjust the cooling time reasonably and use the mold release agent properly to ensure that the cooling state of the products is uniform after demolding. | |

| Product deformation | 1.Uneven plasticization of plastic, excessive or insufficient feeding and filling. 2. The gate positions are improper, asymmetrical or insufficient in number. 3. The mold strength is insufficient, it is prone to deformation, the precision is not high enough or it is damaged, the positioning is unreliable or the ejection position is improper. 4. The demolding system is poorly designed or improperly installed, resulting in uneven force distribution during demolding. 5. The plastic material temperature is too low, the mold temperature is low, the injection nozzle aperture is small, and the shear stress is large when the injection pressure speed is high. 6. When the material temperature is high, the mold temperature is high, the filling effect is excessive, the holding pressure and feeding are too large, and the injection pressure is high, the residual stress is too large. 7. Uneven thickness of the product, improper parameter adjustment, uneven cooling or uneven shrinkage. 8. The cooling time parameter is set too short, causing deformation of the demolded products. The deformation of the products is not properly treated or stored. 9. Uneven mold temperature, uneven cooling, slow cooling of the thick wall parts, fast cooling of the thin wall parts, or rapid cooling of the protruding parts of the plastic part The concave part cools down slowly. | 1.Adjust the reclining position of the screw to reduce the feeding, lower the injection pressure or increase the pressure 2. Change the gate or control the flow rate at the gate. 3. Inspect or modify the mold or install and correct it to ensure accurate positioning, good precision and appropriate ejection position. 4. The design can be modified or reinstalled and debugged to ensure uniform force distribution when the product is demolded. 5. Increase the temperature of the melt cylinder and the mold, and reduce the injection pressure and speed to prevent excessive shear stress. 6. Reduce the temperature of the melt cylinder and the mold, decrease the injection pressure and hold pressure for feeding to prevent excessive residual stress. 7. Check whether the mold is heated evenly, or modify the mold to make its thickness uniform, or adjust the parameters reasonably to make the shrinkage uniform. 8. Increase the setting value of the cooling time parameter, adjust other parameters, strengthen the post-treatment process and ensure reasonable storage and stacking to avoid external factors Deformed by force. 9. Adjust the mold cooling system to control and evenly distribute the mold temperature, avoiding uneven cooling causing uneven temperature, uneven shrinkage and deformation of the plastic part. |

Komoditas mould_taichu jiifeng Mould Co.,Ltd. (jfmoulds.com)

Informasi terkait

Pengaturan suhu cetakan injeksi dan parameter waktu

2025-07-27

Pengaturan suhu cetakan injeksi dan parameter waktu1. Pengaturan Te ...

Cacat umum produk cetakan injeksi dan solusinya

2025-07-29

Cacat umum produk cetakan injeksi dan solusinya diagnosis ...

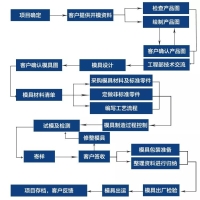

Kumpulan proses manufaktur cetakan, standar, proses, dan kasus.

2025-06-19

Grafik aliran proses adalah sebagai berikut: semua jenis alat dan produk digunakan di Anda...

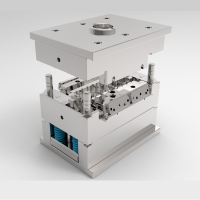

Cetakan injeksi: analisis komprehensif dari pengerjaan presisi hingga beragam aplikasi

2025-06-30

Cetakan injeksi: analisis komprehensif dari pengerjaan presisi hingga penyelam...

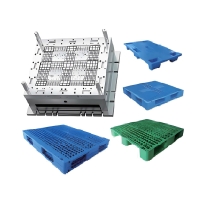

Karakteristik kinerja dan kriteria pilihan cetakan injeksi

2025-06-30

Karakteristik kinerja dan kriteria pilihan cetakan injeksi ini...

Cetakan injeksi umumnya digunakan enam jenis bahan cetakan

2025-06-19

Pilihan besi bukan hanya mempengaruhi kehidupan manusia jamur, namun juga ada...