Dekonstruksi industri cetakan injeksi secara mendalam: terobosan teknologi, rekonstruksi pasar, dan peningkatan dimensi Ekologis

Dekonstruksi industri cetakan injeksi secara mendalam: terobosan teknologi, rekonstruksi pasar, dan peningkatan dimensi Ekologis

I. Kedalaman Teknologi: Dari terobosan titik tunggal hingga inovasi sistematis

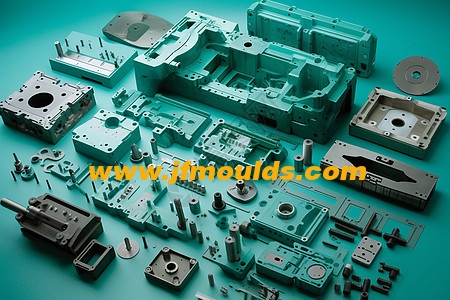

Produsen aksesori crossbeam radiator mobil di Tiongkok (jfmoulds.com)

(1) Cetakan pintar: memulai era "evolusi diri"

Pada tahun 2024, tingkat penetrasi cetakan pintar akan meningkat menjadi 27%, dan intinya telah bergeser dari "pengumpulan data" ke terobosan di lapisan "pengambilan keputusan kognitif". Sensor MEMS yang dibangun ke dalam cetakan (dengan ukuran dikurangi menjadi 3mm × 3mm) dapat menangkap perubahan halus dari perbedaan puncak gelombang tekanan <0,05mpa dan gradien suhu <0,2 ℃ selama proses cetakan injeksi. Dikombinasikan dengan algoritma ringan Tensorflow Lite, ia menyadari:

Prediksi cacat

Dua siklus sebelum tembakan pendek dan flash terjadi, peringatan dikeluarkan, mengurangi laju cacat cetakan bagian interior otomotif tertentu dari 4,2% menjadi 0,3%.

Memproses adaptasi diri

Ketika indeks PP Melt berfluktuasi dengan ± 0,6g/10 menit, tekanan penahan (akurasi ± 0,1mpa) dan laju aliran air pendingin (akurasi ± 0,5L/menit) secara otomatis disesuaikan, dan stabilitas proses meningkat sebesar 45%.

Kembar digital umur

Berdasarkan model kopling termodinamika 3D dari keausan cetakan, kesalahan prediksi masa pakai rongga cetakan kurang dari 5%, dan biaya pemeliharaan cetakan alat rumah tangga tertentu berkurang sebesar 32%.

(2) Revolusi Material: Perluasan Eksponensial dari Batas Kinerja

Inovasi bahan matriks

Ukuran partikel karbida dari baja berkecepatan tinggi generasi keempat (seperti versi modifikasi nanometer ASP-80) disempurnakan menjadi 0,8μm. Dalam cetakan injeksi PA6 + 40% GF, umur cetakan melebihi 1 juta siklus cetakan, yang 25% lebih tinggi dari baja generasi ketiga.

Bahan komposit berbasis magnesium (MG-10% al₂o₃) memiliki kepadatan hanya 1,8g/cm³ dan konduktivitas termal 160W/m · k. Dalam cetakan tutupan antena stasiun pangkalan 5G, ia mencapai pengurangan berat badan 40% dan pemendekan siklus pendinginan 30%.

Terobosan di rekayasa permukaan

Lapisan karbon seperti berlian (DLC) mengurangi kekerasan permukaan cetakan hingga 8000hv melalui plasma yang ditingkatkan uap kimia (PECVD). Dalam PPS cetakan injeksi plastik suhu tinggi, gaya demolding berkurang 75%, memecahkan titik nyeri industri dari "cetakan yang menempel dan mengotori".

Lapisan gabungan graphene (dengan ketebalan kurang dari 5μm) memiliki peningkatan 8 kali lipat dalam ketahanan aus dan ketahanan korosi tiga kali lipat dari stainless steel, menjadikannya konfigurasi standar untuk cetakan bagian plastik dalam peralatan laut.

Ii. Permainan Pasar: "Pergeseran Daya" di lanskap global

(1) "waxing dan waning" dari sabuk industri global

Nilai output cetakan injeksi China menyumbang 45% dari total global. Cluster industri di Taizhou dan Dongguan telah mencapai pengembangan leapfrog berdasarkan "ketebalan teknis + fleksibilitas biaya + kecepatan respons".

Pada tahun 2023, nilai ekspor cetakan mobil dari Taizhou meningkat 25% tahun-ke-tahun, menerobos monopoli Jerman dan Jepang di daerah-daerah seperti tudung mobil (dimensi 1800mm × 1200mm, toleransi ± 0,05mm) dan rangka kursi (permukaan melengkung kompleks + cetakan instan instan).

Cetakan Dongguan 3C telah mencapai toleransi 0,02mm dan 95% pemrosesan otomatis dalam cetakan seri Huawei Mate dan Apple Watch Ultra, dengan tingkat hasil melebihi 98%.

Kekuatan cetakan tradisional berada dalam "kesulitan transformasi": model aset berat industri Jerman 4.0 telah menyebabkan peningkatan 40% dalam biaya pesanan kecil dan menengah, dan pangsa pasarnya telah terkikis sebesar 18% oleh Cina dan Vietnam. Kekurangan teknisi cetakan di Jepang telah berkembang menjadi 25.000, memaksanya untuk melakukan outsourcing 35% dari kapasitas produksi cetakannya ke Asia Tenggara, dan risiko spillover teknologi telah meningkat.

(2) "Stratifikasi Tepat" dari tuntutan regional

Pasar Amerika Utara

The expansion of Tesla's Texas Gigafactory and Boston Scientific Medical production lines has given rise to the demand for "mold + mass production collaboration", and they are willing to pay a 35% premium for 48-hour rapid mold repair and full life-cycle mold management.

European market

The REACH regulation has added 22 restricted substances. Molds for biodegradable materials (such as PBS and PHA) must meet the dual indicators of "no residue + microbial tolerance". It promotes joint research and development by "mold enterprises + material manufacturers". DSM of the Netherlands and China Haitian have jointly established a "biodegradable material mold Laboratory".

Southeast Asian market

Samsung's display module factory in Vietnam and Xiaomi's mobile phone factory in Indonesia have started production, leading to a sudden surge in demand for "standardized mold bases + 96-hour delivery". Chinese mold enterprises have set up bonded warehouses in Thailand to achieve "zero inventory and immediate delivery" of molds. In 2023, the export volume to ASEAN increased by 42%.

Mould_Taizhou jiifeng Mould Co.,Ltd. (jfmoulds.com)

Iii. Ecological Evolution: The "Synergistic Leap" of Industrial Chains

(1) The explosive development of the "Mold +" ecosystem

Mold + Intelligent Manufacturing

Haitian's "Moyun" system has connected over 500 processing devices. Through digital twins, it enables full-process visualization of mold design, manufacturing, and operation and maintenance, reducing the delivery cycle by 40%. Yinbaoshan has newly developed a "Mold Metaverse" platform, where customers can experience the mold trial process in VR, and the order conversion rate has increased by 28%.

Mold + Circular Economy

The scale of the mold remanufacturing industry has exceeded 6 billion yuan. Xometry has launched a "mold carbon footprint traceability" service, reducing the carbon emissions of repaired molds by 65% compared to new molds. Dongguan Jingsheng has established a mold recycling industrial park, capable of processing 20,000 tons of used molds annually, with a reuse value exceeding 300 million yuan.

Mold + Green Manufacturing

The penetration rate of dry cutting in mold enterprises in the Yangtze River Delta has reached 70%. Combined with an oil mist recovery system, a single factory can reduce carbon emissions by 2 tons annually. The application proportion of bio-based mold materials (such as bamboo fiber reinforced PLA) in children's toy molds reaches 15%, and the carbon emissions throughout their life cycle are reduced by 70%.

(2) The "Dimensional Upgrade Campaign" of Chinese Enterprises

Technical breakthroughs

The 0.5mm wall thickness 5G base station filter mold developed by Huawei's supplier adopts the "gas-assisted injection molding + in-mold electroplating" technology, and the yield rate has increased from 55% to 95%.

Byd's 3M-level battery tray integrated mold, through a composite process of "molding + injection molding + carbon fiber reinforcement", reduces weight by 30% and increases production efficiency by 35%.

Brand Breakthrough

Haitian and Yizhimi led the formulation of 12 international mold standards. The "Detection Method for Surface Roughness Ra0.01μm in China" and the "Industry Specification for Temperature Fluctuation of Hot Runner ±1℃" were included in the ISO standards.

Changying Precision has achieved a 0.01mm tolerance and a lifespan of 700,000 mold cycles for Apple's AirPods molds, with a brand premium of 50%, breaking the monopoly of American and Japanese enterprises in precision molds for consumer electronics.

Supply chain autonomy

The "ultra-pure die steel" process of Baosteel Special Steel makes the impurity content of DC53 steel less than 0.005%, and its performance surpasses that of Japan's Daido Steel. The replacement rate of mobile phone middle frame molds exceeds 80%.

Harbin Institute of Technology Intelligent and Huazhong University of Science and Technology jointly established the "Mold Intelligent Equipment Laboratory", breaking through the "bottleneck" technology of five-axis linkage machine tools, and achieving a mold processing accuracy of ±0.003mm.

Iv. Future Vision: Dual-Driven by Technology and Market in 2025

1."Mold as a Service (MaaS) 2.0" : Mold enterprises have upgraded from "capacity leasing" to "technology + data subscription", such as providing "mold AI algorithm packages" and "process optimization cloud services", and have been the first to be implemented in the medical and automotive core component fields.

2. Cross-domain technology integration: Aerospace "structural topology optimization" and biomedical "cell-level bionic design" deeply empower molds. The automotive bumper mold adopts a honeycomb bionic structure, reducing weight by 40% while enhancing impact resistance by 30%.

3. AI Full-chain penetration: Generative AI automatically generates 3D structures for molds (increasing design efficiency by 60%), the AI production scheduling system enables equipment utilization rates to exceed 90%, and predictive maintenance reduces mold sudden failures by 80%.

4. Regional ecological rise: The mold matching rate in Chengdu-Chongqing (an automotive industrial cluster) and Nantong (a manufacturing hub in the northern wing of the Yangtze River Delta) exceeds 85%, forming a closed loop of "R&D - manufacturing - testing", reducing the supply chain response time by 25%.

As the "crown jewel" of the manufacturing industry, the development of injection molds has become a core symbol of a country's technological strength and industrial resilience. Under the triple impetus of technological breakthrough (intelligence + materials), market reconstruction (global transfer + regional in-depth development), and ecological upgrading (collaboration + autonomy), China's mold industry is rewriting global industrial rules with "systematic competitiveness", and the leap from a "mold giant" to a "mold power" has entered a critical sprint period. Every opening and closing of the mold will become a footnote to the upgrading of China's manufacturing industry.

Informasi terkait

Dari mendasar hingga aplikasi, bagaimana ia mempengaruhi hidup kita

2025-07-17

Dari hal-hal hingga aplikasi, bagaimana ia mempengaruhi konsep dasar livesThe kami...

Kartu Bisnis Baru dari Mold Capital sepenuhnya dimulai.

2025-06-19

Baru-baru ini, di situs konstruksi cetakan Huangyan manufaktur cerdas...

Analisis mendalam industri cetakan injeksi

2025-07-01

Analisis mendalam cetakan injeksi IndustryI. Contoh umum mengenai Injection Mol...

Menjelajahi cetakan injeksi: membuka kode inti cetakan plastik

2025-07-10

Menjelajahi cetakan injeksi: membuka kode inti cetakan plastik di...

Evolusi koordinat tentang iterasi teknologi dan ekosistem industri

2025-07-15

Evolusi koordinat tentang iterasi teknologi dan ecosystemI industri...

Dekonstruksi industri cetakan injeksi secara mendalam: terobosan teknologi, rekonstruksi pasar, dan peningkatan dimensi Ekologis

2025-07-03

Dekonstruksi industri cetakan injeksi secara mendalam: Breakthrou teknologi...