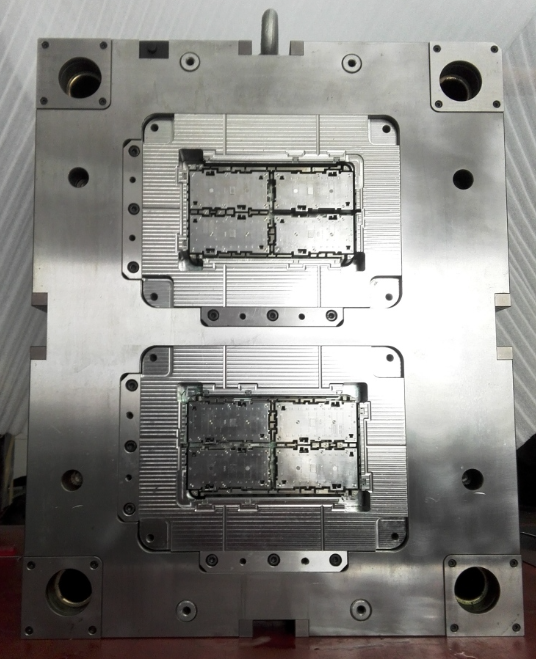

Gambar cetakan dan tinta gerbang

Gambar cetakan dan tinta gerbang

Gambar cetakan

Fenomena: Kedua produk tersebut adalah produk bertekstur dan ada fenomena penarikan cetakan.

Analisis: Kecepatan lambat akan menyebabkan produk menjadi terlalu cepat. Posisi switching terlalu lambat.

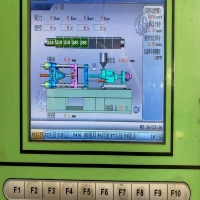

Karakteristik mesin cetakan injeksi

Kelas: Demag (Ningbo), kekuatan penjepit: 120T, kapasitas plastisisasi: 130g.

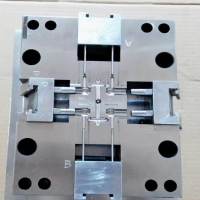

(2) Karakteristik jamur

Nomor ejeksi cetakan: 1 × 2, Metode Injeksi Lem: Gerbang Titik, Metode Ejeksi: Ejeksi Pelat Push, Suhu Cetakan: 90 ° C (Mesin Suhu Konstan).

(3) Bukti fisik produk

Bahan: PC+ABC HP5004-100, Warna: Hitam, Berat Produk (Single Piece): 3.2g, Berat Nozzle: 13G.

(4) Analisis penyebab cacat

1. Saluran utama cetakan panjang dan tipis. Metode inlet lem adalah inlet lem submersible. Bahan cair mengalir di dekat inlet lem. Karena kecepatan lambat, tekanan lokal produk terlalu besar, menghasilkan fenomena penarik cetakan.

2. Keterbatasan yang melekat pada peralatan itu sendiri telah menyebabkan ketidakmampuan untuk memperbaiki situasi melalui penyesuaian mesin.

(5) Penanggulangan

Produk yang didebug setelah mengganti mesin Demag 100T memenuhi syarat, dan kecepatan injeksi mesin dapat mencapai 220mm/s.

Tabel proses cetakan injeksi

Mesin cetakan injeksi: Haiti 1201T, sekrup tipe B, volume injeksi 131g | Nama Produk: Bingkai Baterai M169 | ||||

Bahan baku: ABS+PC HP5004 | Warna: Hitam | Suhu pengeringan: 100 ° C. | Metode Pengeringan: Pengering Dehumidifying | Waktu pengeringan: 4 jam | Penggunaan Bahan Daur Ulang: 0 |

| Berat produk jadi: 3.2g × 2 = 6.4g | Berat Nozzle: 13G | Output cetakan: 1 × 2 | Metode Injeksi Gerbang: Gerbang Titik | ||

| Suhu barel | Suhu jamur | Gunakan mesin | "Pengaturan | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 110°C | 102°C |

| 320°C | 315°C | 315°C | 300°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 110°C | 101°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 |

| ||

| / | 3 | Holding pressure time | 12 | 12 |  Injection pressure position Injection pressure position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 |  Injection velocity Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 |  Velocity of fire position Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Mould_Taizhou jiifeng Mould Co.,Ltd. (jfmoulds.com)

Mold ink flushing

Phenomenon: Ink surges at the gate of the S10 face frame.

Reason: During IML injection molding, the gate of the sheet material often appears transparent.

Analysis: High speed will cause material melting, intensify shearing and generate high temperatures. The ink has poor heat resistance.

Karakteristik mesin cetakan injeksi

Grade: DEMAG (Ningbo), clamping force: 50T, plasticizing capacity: 42g.

(2) Karakteristik jamur

Mold ejection number: 1×2, glue injection method: point gate, ejection method: push plate ejection, mold temperature: 70°C (constant temperature machine).

(3) Karakteristik produk

Material: ABS PA758, Color: Transparent, Product weight (single piece) : 1.5g, sprue weight: 13g.

(4) Analisis penyebab cacat

1.The main channel of the mold is quite large, and the glue inlet method is submersible glue inlet. When the molten material flows near the glue inlet, due to the excessive speed, it causes high shear, resulting in a rapid and instant temperature rise of the molten material.

2. The ink is not resistant to high temperatures, resulting in ink flushing.

(5) Penanggulangan

1.Utilize multi-level injection and position switching.

2. In the first section, fill the flow channel to the glue inlet at a relatively fast speed and find the corresponding switching position. Then, in the second section, fill the area near the glue inlet at a slow speed and a very small position. In the third section, quickly fill 90% of the mold cavity to prevent the high-temperature molten rubber from cooling. In the fourth section, slowly fill the mold cavity. Finally, switch to the pressure-holding switching position.

Tabel proses cetakan injeksi

Mesin cetakan injeksi: demag50t, sekrup tipe B, kapasitas injeksi 42g | Product Name: Transparent Mirror | ||||

Raw material: ABS PA758 | Warna: Transparan | Drying temperature: 70°C | Metode Pengeringan: Pengering Dehumidifying | Waktu pengeringan: 2 jam | Penggunaan Bahan Daur Ulang: 0 |

| Finished product weight: 1.5g×8=12g | Berat Nozzle: 13G | Mold output: 1×8 | Metode Injeksi Gerbang: Gerbang Titik | ||

Suhu barel | Suhu jamur | Gunakan mesin | "Pengaturan | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 70°C | 72°C |

| 260°C | 255°C | 250°C | 210°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 70°C | 71°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 |  Injection pressure Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 |  Injection pressure position Injection pressure position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 |  Injection velocity Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 |  Velocity of fire position Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Komoditas mould_taichu jiifeng Mould Co.,Ltd. (jfmoulds.com)

Informasi terkait

Panduan komprehensif cetakan injeksi: mulai dari dasar hingga penerapan

2025-07-11

Panduan komprehensif cetakan injeksi: mulai dari dasar hingga penerapan di vas...

Pengaturan suhu cetakan injeksi dan parameter waktu

2025-07-27

Pengaturan suhu cetakan injeksi dan parameter waktu1. Pengaturan Te ...

Diversifikasi perusahaan cetakan injeksi

2025-06-28

Diversifikasi cetakan injeksi enterprise1. Cetakan otomotif: lekukan kemudi...

Penyebab dan solusi penyok pada produk cetakan injeksi, produk jadi yang tidak lengkap, dan flash pada produk

2025-07-29

Penyebab dan solusi penyok pada produk cetakan injeksi, finis yang tidak lengkap ...

Pengaturan Parameter Tekanan dan Aliran Cetakan Injeksi

2025-07-26

Pengaturan Parameter Tekanan dan Aliran Injeksi1.Setting suntikan ...

Posisi cetakan berbentuk U diisi dengan saluran air dan udara yang terperangkap, yang berubah menjadi putih

2025-08-06

Posisi cetakan berbentuk U diisi dengan saluran air dan udara yang terperangkap, wh ...

Injection pressure

Injection pressure