Cara memecahkan masalah penyok permukaan dan jamur pada cetakan injeksi

Cara memecahkan masalah penyok permukaan dan jamur pada cetakan injeksi

Titik cekung di permukaan cetakan injeksi

Fenomena: bintik -bintik cekung di permukaan bingkai wajah

Alasan: Selama cetakan injeksi in-mold dari bahan lembar IML, banyak titik cekung muncul di permukaan produk.

Analisis: Ada sedikit debu di permukaan lembaran PC. Kebersihan udara di lingkungan tidak tinggi, dan ada banyak debu, yang menyebabkan depresi terjadi ketika lembaran ditempatkan di cetakan untuk cetakan injeksi.

(1) Karakteristik mesin cetakan injeksi

Grade: Demag, Clamping Force: 50t, Plastisisasi Kapasitas: 42g.

(2) Karakteristik jamur

Nomor ejeksi cetakan: 1 × 2, Metode Injeksi Lem: Gerbang Titik, Metode Ejeksi: Ejeksi dengan pin ejector, suhu cetakan: 70 ° C (mesin suhu konstan)

(3) Bukti fisik produk

Bahan: ABS PA758, Warna: Transparan, Berat Produk (Single Piece): 2.4G, bobot sariawan: 8.44g.

(4) Analisis penyebab cacat

1. Ada sedikit debu di permukaan lembaran PC. Ketika ditempatkan dalam cetakan untuk cetakan injeksi, bintik -bintik debu disuntikkan ke permukaan produk.

2. Lingkungan udara bersih dengan banyak debu. Ketika cetakan dibuka, debu melekat pada permukaan inti cetakan depan dan menyebabkan titik cekung ketika cetakan berikutnya didaur ulang.

(5) Penanggulangan

1. Bersihkan permukaan bahan lembaran secara manual untuk meminimalkan titik debu.

2. Murni kemurnian udara dan secara teratur membersihkan mesin dan lingkungan sekitarnya.

Tabel proses cetakan injeksi

Mesin cetakan injeksi: demag50t, sekrup tipe B, kapasitas injeksi 42g | Nama Produk: Bingkai Wajah S10 | ||||

Bahan Baku: ABS PA785 | Warna: Transparan | Suhu pengeringan: 80 ° C. | Metode Pengeringan: Pengering Dehumidifying | Waktu pengeringan: 2 jam | Penggunaan Bahan Daur Ulang: 0 |

Finished product weight: 2.4g×2=4.8g | Nozzle weight: 8.44g | Mold output: 1×2 | Gate injection method: Point gate | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Water temperature machine | 70°C | 62°C |

| 260°C | 255°C | 250°C | 220°C | / | ||||

| △ | △ | △ | △ | △ | after | Water temperature machine | 70°C | 59°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 | Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 | Injection position | ||||

Residual amount of injection glue | 10 | / | 55 | 3 | Injection velocity | ||||

| 7.8 | / | / | 12 | 23.5 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Mould_Taizhou jiifeng Mould Co.,Ltd. (jfmoulds.com)

The injection mold is moldy

Reason: This is an IML injection molded product. Due to the temperature difference on the mold surface when the sheet is installed, it forms a semi-transparent state.

Analysis: High speed will cause material melting, intensify shearing, generate high temperatures and be prone to decomposition. The surface temperature of the mold is too low. The temperature of the material pipe is too low.

(1)Characteristics of injection molding machines

Grade: DEMAG (Ningbo), clamping force: 50t, plasticizing capacity: 42g.

(2) Karakteristik jamur

Mold ejection number: 1×2, glue injection method: point gate, ejection method: Ejection by ejector pin, mold temperature: 60°C (constant temperature machine)

(3) Bukti fisik produk

Material: ABS PA758, Color: Transparent, Product weight (single piece) : 2.43g, sprue weight 8.44g.

(4) Analisis penyebab cacat

The mold temperature is low, and the inlet method is potential inlet. The molten material flows to the vicinity of the inlet. Due to the excessive speed and the very smooth surface of the mold, high shear occurs, causing the molten material to heat up rapidly in an instant, until the surface turns white and forms a semi-transparent state.

(5) Countermeasures

1. Memanfaatkan injeksi multi-level dan switching posisi.

2. Appropriately increase the mold temperature to allow the product to cool down slowly in the mold.

3. Appropriately increase the temperature of the melt cylinder to enhance the transparency of the product.

Tabel proses cetakan injeksi

| Injection molding machine: Demag 50T, Type B screw, injection capacity 42g | Product Name: S10 Face Frame | ||||

| Raw material: ABS PA758 | Warna: Transparan | Suhu pengeringan: 80 ° C. | Metode Pengeringan: Pengering Dehumidifying | Waktu pengeringan: 2 jam | Penggunaan Bahan Daur Ulang: 0 |

Finished product weight: 2.43g×2=4.86g | Nozzle weight: 8.44g | Mold output: 1×2 | Gate injection method: Point gate | ||

Barrel temperature | Mold temperature | Use machines | "Settings | "Actual | ||||

| 1 | 2 | 3 | 4 | 5 | before | Oil temperature control machine | 80°C | 73°C |

| 242°C | 236°C | 227°C | 200°C | / | ||||

| △ | △ | △ | △ | △ | after | Oil temperature control machine | 80°C | 67°C |

| △ | △ | △ | △ | △ | ||||

| / | 50 | Holding pressure | Pressure-holding position | 100 | 110 | 120 | Injection pressure | ||

| / | 3 | Holding pressure time | 12 | 12 | Injection position | ||||

Residual amount of injection glue | / | 10 | / | 55 | 3 | Injection velocity | |||

| 7.8 | / | / | / | 12 | 23.5 | Velocity of fire position |

Intermediate time | Injection time | Cooling time | The entire duration | Back pressure | Rotational speed | Retraction speed | Material quantity position | Retraction position |

| 1 | 5 | 10 | 25 | 5 | 10 15 10 | 10 | 38 | 3 |

Mold closing protection time | Supervise the feeding time | Clamping force | Ejection length | Ejection times | Rotation position | Blowing delay | Blowing time |

| 1 | 10 | 60 | 45 | 1 | 15 35 38 | / | / |

Komoditas mould_taichu jiifeng Mould Co.,Ltd. (jfmoulds.com)

Informasi terkait

Peralatan utama di bidang logistik dan pergudangan

2025-06-29

Peralatan utama di bidang logistik dan produsen cetakan pergudangan di...

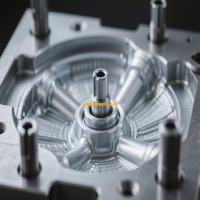

Cetakan injeksi: analisis komprehensif dari pengerjaan presisi hingga beragam aplikasi

2025-06-30

Cetakan injeksi: analisis komprehensif dari pengerjaan presisi hingga penyelam...

Penyebab dan solusi pengelasan yang buruk dalam cetakan injeksi, retakan produk dan deformasi produk

2025-07-30

Penyebab dan solusi pengelasan yang buruk dalam cetakan injeksi, produk memecahkan ...

Teknologi gerbang cetakan injeksi

2025-07-23

Teknologi gerbang cetakan injeksi Systemauto mould_taizhou jiefeng cetakan co., ...

Cacat umum produk cetakan injeksi dan solusinya

2025-07-29

Cacat umum produk cetakan injeksi dan solusinya diagnosis ...

Struktur, bahan dan desain cetakan injeksi

2025-07-18

Struktur, bahan dan desain cetakan injeksi di lanskap yang luas...